News Center

LATEST NEWS

Address: 3rd floor, Building 6, 30 Fortress Road, Gongming Street,

Guangming District, Shenzhen 518106

Email:sales@hyzk-electronics.com

Phone:0086 18682384515

Industry articles

HomeIndustry articlesDetails

PCBA Automation Production Line Exploration and Outlook

Publish: 2025-05-16 12:41:33 Update: 2025-05-18 13:14:26 View: 175

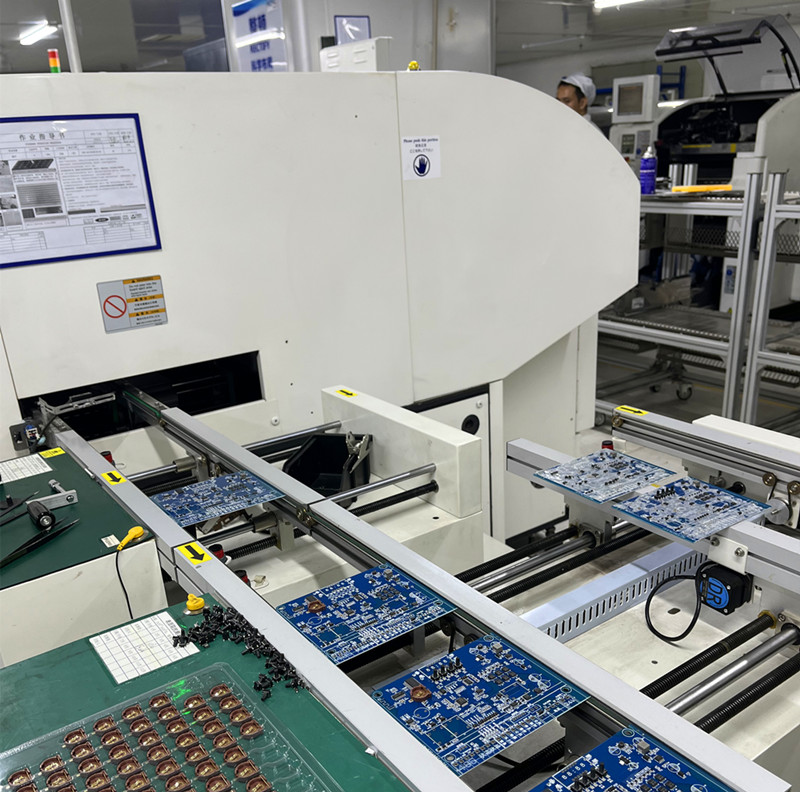

In the trend of intelligent manufacturing, PCBA (Printed Circuit Board Assembly) automation production line as the core pillar of the electronics

manufacturing industry, is driving the industry change and upgrade at an unprecedented rate. This article will delve into the mystery of PCBA

automation production line, revealing its cornerstone position in intelligent manufacturing.

The rise of automated production lines

With the rapid development of information technology and the advancement of industrial intelligence, PCBA automation production lines have

become an integral part of the electronics manufacturing industry. These production lines integrate advanced automation equipment, precision

mechanical transmission technology and intelligent control system, achieving a fully automated production process from component assembly,

welding to inspection. The application of automation production lines not only greatly improves production efficiency, but also significantly reduces

labor costs and error rates, laying a solid foundation for intelligent manufacturing.

Key technologies for automated production lines

1. Tin paste printing machine

As the first step in the PCBA production line, the tin paste printing machine is responsible for printing the tin paste precisely on the welding plate of the

circuit board. Modern tin paste printing machines provide a solid foundation for subsequent patching and welding by ensuring that the amount of tin paste

on each welding plate is uniform through high-precision packaging, tin-adding paste, printing and transmission boards.

2. SMT machine

The SMT machine is the key equipment in the PCBA production line, it accurately places the surface mounting components on the welding plate of the circuit

board by moving the mounting head. The advanced patching machine has a high level of automation and intelligence, which can cope with complex and

changing component mounting needs, greatly improving production efficiency and mounting accuracy.

3. Reflow welding

The reflow welding is the key equipment for achieving welding in PCBA production. Its internal heating circuit heats air or nitrogen to a sufficiently high

temperature and blows it to the circuit board where the weld on both sides of the component is glued to the motherboard after melting. The advanced reflow

welding furnace has a precise temperature control system and efficient thermal energy utilization capability to ensure stable and reliable welding quality.

4. AOI Machine

AOI (Automatic Optic Inspection) machine is based on optical principles to detect common defects in welding production. By automatically scanning the circuit

board, capturing images and comparing them with qualified parameters in the database, AOI detectors can accurately detect defects on the circuit board and

display them via a display or automatic logo for repair personnel.

5. Industrial Internet of Things and Artificial Intelligence

In addition to the above key equipment, the application of industrial IoT and artificial intelligence technology is also an important component of the PCBA automation

production line. Through sensors, device interconnection and data acquisition analysis, the industrial IoT achieves equipment status monitoring, production process

control and optimization. And artificial intelligence technologies such as machine learning, deep learning, etc., further optimize production scheduling, predict equipment

failure, improve the level of production line automation, and realize intelligent production management.

The advantages and challenges of automated production lines

Advantages:

1.Improve production efficiency: the automated production line can work 24 hours without interruption, greatly improving production efficiency.

2.Reduce labor costs: reduce dependence on labor, reduce labor costs.

3.Improve product quality: the high accuracy and stability of automation equipment ensures the stable improvement of product quality.

4. Optimize resource allocation: through intelligent production management, to achieve the optimal allocation of resources and efficient use.

Challenges:

1. Rapid technological update: it is necessary to continuously invest in research and development to follow the development of new technologies.

Talent training: the operation and maintenance of the automation production line requires professional technical talents.

Data security: As the volume of data increases, how to ensure data security becomes a new challenge.

Conclusion

As the cornerstone of intelligent manufacturing, PCBA automation production line is leading the electronics manufacturing industry towards more efficient

and intelligent development. Through continuous technological innovation and optimization upgrade, PCBA automation production line will bring more

possibilities and opportunities for intelligent manufacturing. In the future, with the continuous progress of technology and the expansion of application

scenarios, PCBA automation production line will play a more important role in the field of intelligent manufacturing.